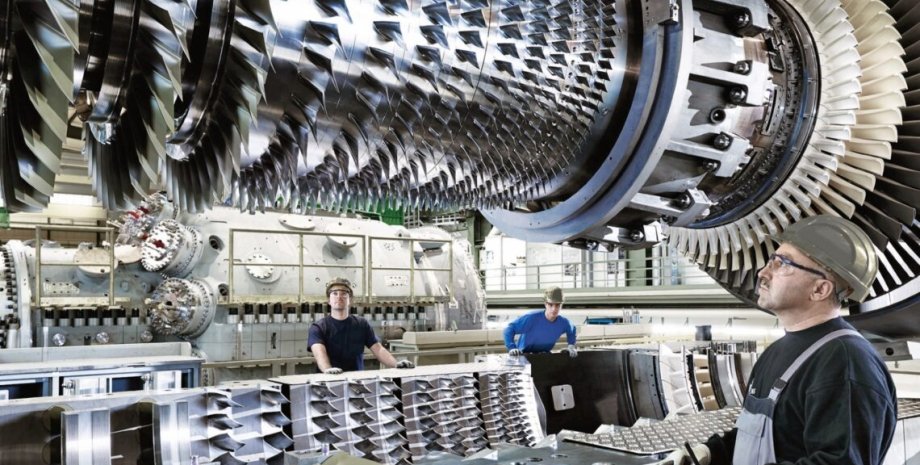

The HyflexPower project is aimed at demonstrating the potential of hydrogen as an environmentally friendly and affordable energy for electricity and heat production, as well as to present alternative ways to reduce carbon emissions. The tests take place at the Smurfit Kappa paper packaging plant in Saya-sur-Vienne, France. The site is equipped with an industrial gas turbine Siemens Energy SGT-400. It is adapted to work on hydrogen fuel.

One of the main stages of the project was the completion of the transition from 30% of the hydrogen mixture to 100% hydrogen work of the turbine. This development not only proves the potential of hydrogen, but also confirms that existing gas installations can be converted into hydrogen -based technologies. The proposed method combines several applied technologies, such as electrolysis, storage of hydrogen and conversion.

The main advantage of this integration is that it enables the use of renewed hydrogen, which has become a standard for future industrial decarbonization projects. Siemens Energy believes that this introduction of hydrogen use is an economic transformation of a pure, previously rejected energy industry into practical industrial use. The use of a turbine with green hydrogen is a task, not easy.

However, the characteristics of hydrogen, its combustion rate and flame temperature create serious problems in terms of material and safety resistance. The project team was able to turn these problems into opportunities by introducing a new low -emission -burning technology. Moreover, the production of hydrogen needed an electrolyzer with a capacity of 1 MW and storage in the tank with a volume of almost a ton.

This is an important step in technology development because it helps to overcome problems that arise when using hydrogen in production processes, especially in energy-intensive industries, such as cellulose and paper, cement and steel industry.

The project demonstrates that the existing infrastructure can be re-profiled for hydrogen use, thereby providing opportunities for industries that want to reduce gas consumption, for example, from Russia's aggressor country, while maintaining the same level of productivity. Many sectors of industry are still fighting with uninhabited heating, and heat generation technology apparently solves this problem.

The potential of using hydrogen for the production of both electricity and heat from renewable energy, such as wind and sun energy, is revolutionary in how the industry will adapt to green energy. According to the development of the project, the consortium plans to increase technology parameters and to study the possibilities of its commercialization. This project can also help you achieve climate goals as it uses pure hydrogen at any industrial facility.

In addition, it is well consistent with the general purpose of the European Commission to promote the transition to net energy and to assist the industries in achieving pure zero. The HyflexPower initiative is a big step forward in using renewable hydrogen in industrial processes. This improvement illustrates the ability of hydrogen to "change" sectors that are difficult to decarbonize.

All rights reserved IN-Ukraine.info - 2022