By Eliza Popova

By Eliza Popova

Within the framework of the Northrop Agreement, it will provide technical and business consultations, cooperate in projection and testing, and will also offer Space Forge specialists for microelectronics development.

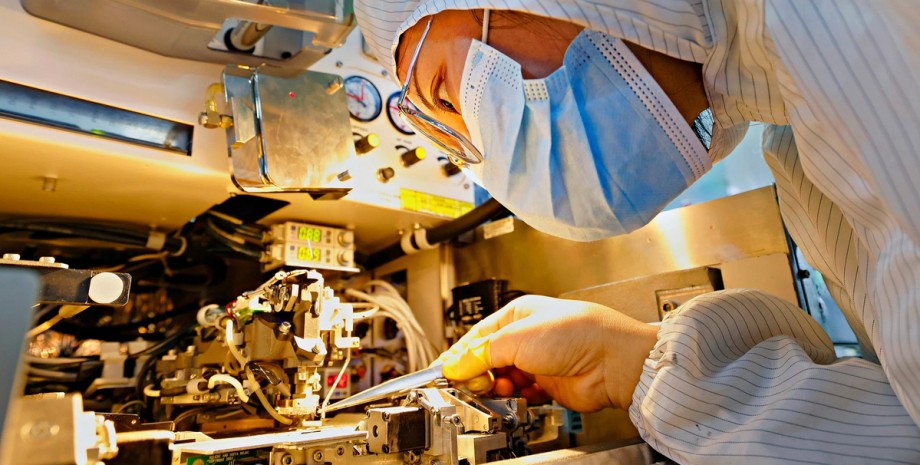

The idea of a startup Space Forge for the production of microelectronics in orbit is that the cosmic environment, especially conditions such as microgravitation and ultra-high vacuum, help to produce higher quality materials and improve the efficiency of some production processes such as 3D printing. Although this concept is not new, it was not allowed to implement too expensive launches into orbit.

With the advent of SpaceX and forecasts for reducing the cost of flights into space, the concept is relevant again.

David Pyle, Regional Director of the Northrop Space Business Sector in the United Kingdom, Europe, Middle East and North Africa, said that although semiconductors who create in space from the very beginning would be more expensive in production due to the cost of their departure in orbit and with It is the goal to promote this production sector and to obtain the highest quality semiconductors for sensitive military systems.

Northrop, which creates a B-21 bomber for the US Air Force and an integrated US Army Combat System, has two foundry plants for raw materials processing on semiconductor chips, which eventually integrated into the main weapons systems. At present, the role of Northrop will mostly be the test of materials produced in space, after their return to Earth.

All rights reserved IN-Ukraine.info - 2022